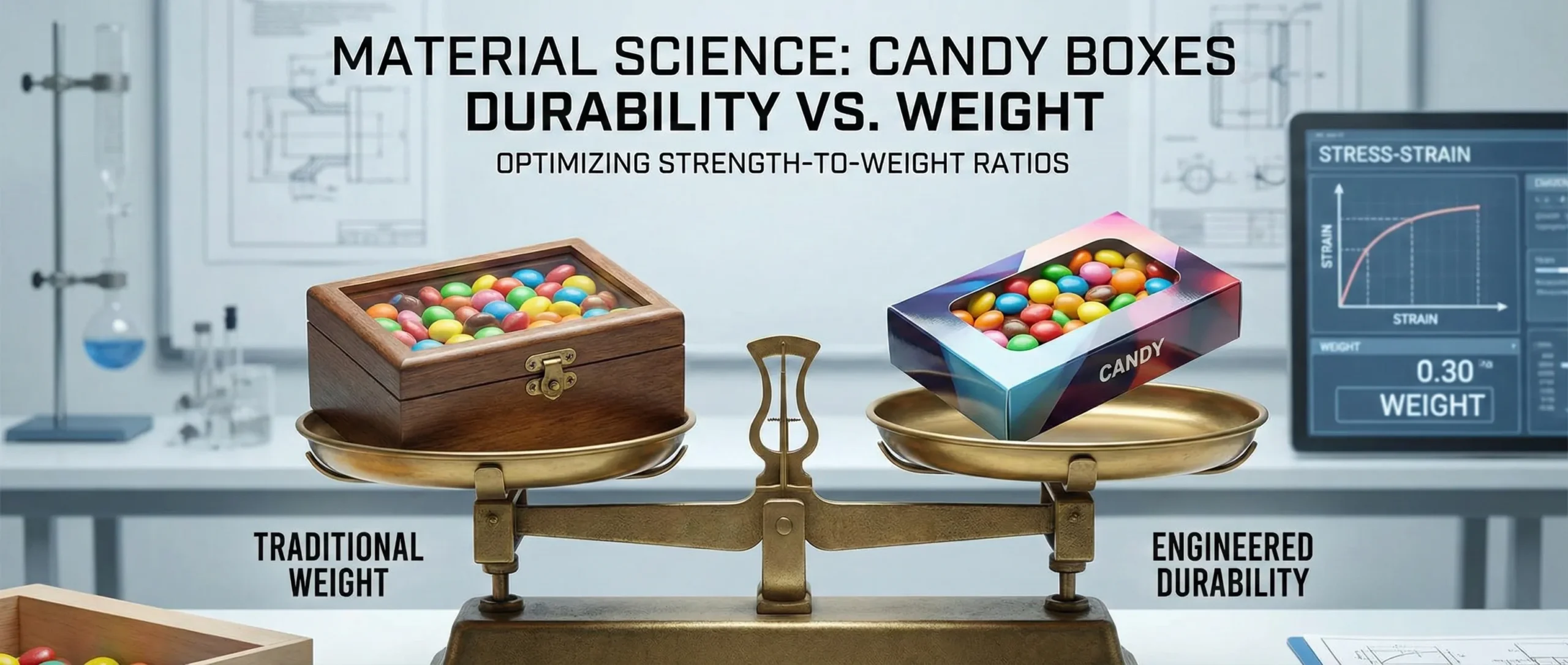

The engineering of confectionery packaging resides at the complex intersection of structural mechanics, polymer physics, and environmental life cycle management. Packaging substrates must serve as an absolute kinetic barrier to moisture vapor and oxygen ingress while maintaining strict structural integrity to prevent mechanical damage during high-velocity transit. This objective dictates the structural optimization of candy boxes.

Mechanical Property Profiling: Elasticity and Tensile Deformation

Quick Answer: How do you measure candy boxes durability against its weight?

The primary metrics governing packaging durability are Young’s Modulus, tensile strength, and elongation at break. A high Young’s Modulus indicates high rigidity, which is essential for load-bearing containers that must resist vertical deformation under stacking pressures.

In biopolymer applications, materials like Polylactic Acid (PLA) exhibit high tensile strength but possess substantial brittleness and lower elongation at break, leading to catastrophic structural failure under sudden mechanical stress. To mitigate this without increasing mass, composite plasticizers are integrated into the polymer matrix to increase the rebound rate, optimizing the mechanical performance of eco-friendly candy packaginges.

Structural Engineering: Micro-Fluted Cellulosic Networks

Quick Answer: What is the optimal corrugated structure for lightweight candy boxes packaging?

E-Flute and F-Flute micro-flutes provide high structural rigidity and an ultra-smooth printable surface without prohibitive weight. Corrugated cardboard functions as a series of connected I-beams, creating internal air cushions that absorb kinetic shocks and impart crush resistance relative to a low basis weight.

The durability of custom candy boxes during warehousing is evaluated via the Edge Crush Test (ECT) and Box Compression Test (BCT). The ECT measures the edgewise compressive strength of the corrugated board. To ensure compliance with automated sortation networks, these structures must be verified against rigorous custom shipping boxes drop test standards.

Nanocomposite Engineering and Moisture Barriers

The primary functional deficit of cellulosic packaging is extreme vulnerability to moisture; internal hydrogen bonds are rapidly plasticized by water molecules, causing fibers to swell and shed their crush resistance. This absorptivity is quantified using the standardized Cobb Test.+2 ( candy Boxes )

To optimize barrier properties without adding physical weight or increasing film thickness, nanocomposites are integrated into the polymer matrix. The dispersion of nanoclays, such as montmorillonite, creates a “tortuous path” model. Gas molecules are forced to navigate around impermeable silicate plates, drastically lowering the oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) of extremely thin, lightweight films.

Validate Your Engineering Transition from theoretical models to physical assurance by certifying your packaging through International Safe Transit Association (ISTA) standards

Their rigorous drop-test protocols verify that your optimized durability-to-weight ratios will survive the kinetic chaos of the global supply chain.

Algorithmic Optimization and Life Cycle Assessment

Finite Element Analysis (FEA) evaluates structural integrity by breaking down the continuous geometry of a box into a discrete mesh to model responses to applied external forces. Computational analysis reveals that the vertical edges bear the vast majority of the compressive load, enabling engineers to deliberately reduce material thickness in central panels to lower overall mass.

For rigid containers, topology optimization algorithms hollow out interior walls to create porous, honeycomb-like internal lattice structures, maximizing the specific strength-to-weight ratio utilizing the absolute minimum volume of plastic. These mathematical models undergo physical validation through official ASTM D7386 testing standards to simulate kinetic impact for your candy boxes.

Engineers must balance these physical weight reductions against the Size-Weight Illusion (SWI), a psychological phenomenon dictating that consumers subconsciously associate physical heft and density with premium product quality and high monetary value.

Executing these optimization algorithms is critical for candy boxes wholesale acquisition. It directly lowers shipping weights, fuel consumption, and associated Scope 3 carbon emissions without risking product damage. Similar logistical frameworks govern the structural mechanics of perishable confectionery transit to maximize supply chain efficiency and product survival.