Cupcake Containers: The commercial transport of gourmet cupcakes presents a unique logistical challenge: the preservation of architectural integrity under variable kinetic and atmospheric conditions. Cupcakes are unstable structures characterized by a high center of gravity and a decorative topping that possesses a specific yield stress. When subjected to the accelerations, decelerations, and vibrations of a delivery vehicle, the forces acting upon the frosting can lead to structural failure, manifesting as smudging, toppling, or wilting.

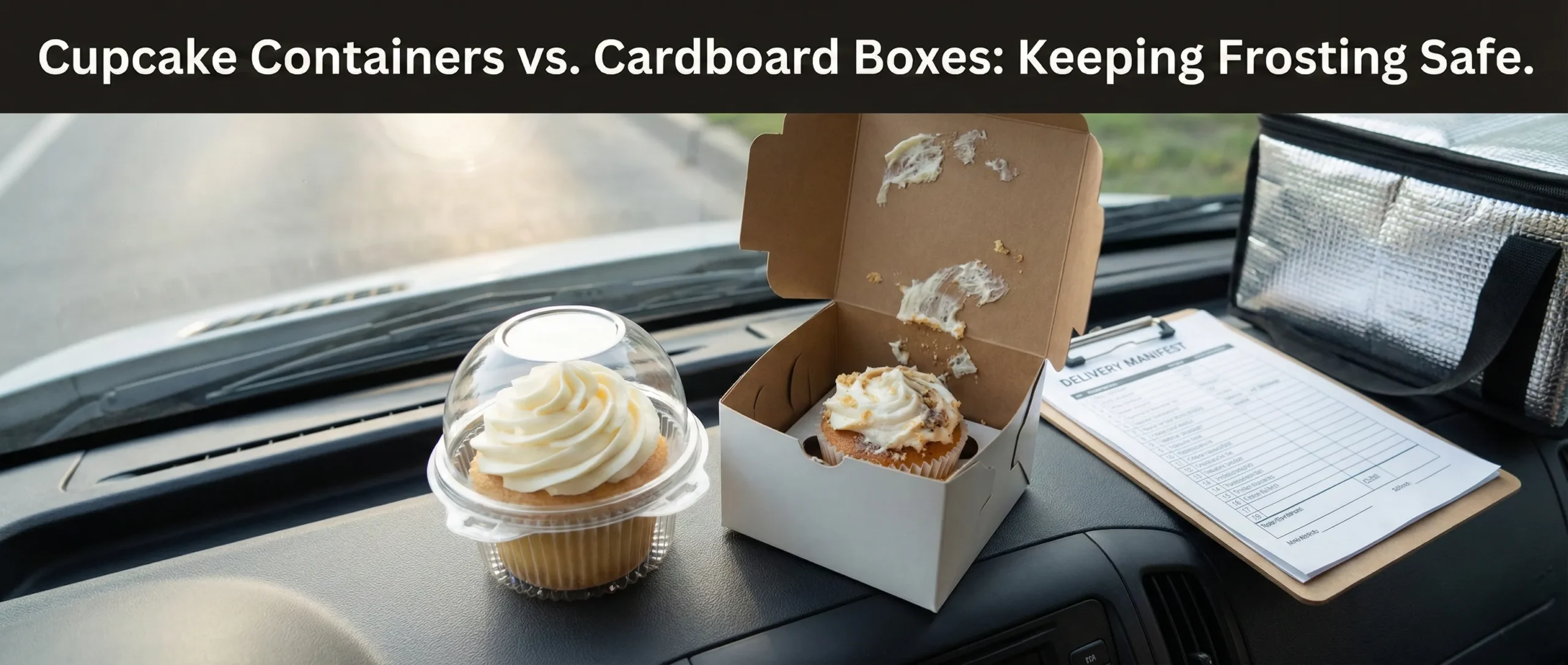

The choice between traditional cardboard systems and modern polymer Cupcake Containers dictates the micro-environmental engineering of the “last mile.” This analysis evaluates how to protect your frosting investments during transit.

Kinetic Energy and Toppling Dynamics In packaging

Quick Answer: > To prevent cupcakes from toppling during cornering or sudden braking, you must manage the transfer of kinetic energy. While manual interventions like “frosting glue” (placing a deposit of buttercream under the liner) increase adhesive force, geometric containment is superior. Individual Cupcake Containers are engineered with contoured wells that provide lateral support to the base of the liner, significantly reducing the degree of freedom for movement. Generic cardboard boxes without precision inserts allow for a higher range of motion, frequently resulting in “frosting disasters” where the piped edges contact the box walls.

Vibration Damping Systems

Delivery vehicles introduce a spectrum of vibrations that can resonate within the frosting structure.

- Cardboard: Functions as a sacrificial shock absorber. The fluted interior layer of corrugated cardboard deforms upon impact, dissipating energy through the compression of air and paper fibers.

- Polymer Containers: High-quality individual cupcake containers are designed with “structural ribs” molded into the sides. These indentations increase the moment of inertia of the walls, redirecting impact forces around the perimeter of the container rather than through the product.

To ensure your primary delivery vessels can withstand automated courier networks before local dispatch, verify your outer packaging meets strict custom shipping boxes drop test standards. Implementing these stabilization principles is identical to the protocols required to learn how to ship cookies without breaking them.

Material Science: Polymer vs. Cellulose

Quick Answer: > Cupcake Containers made from PET (Polyethylene Terephthalate) provide a 360-degree view, allowing delivery personnel to verify frosting integrity without breaking the seal. They also feature “deep-dome lids,” providing an additional 0.5 to 1.0 inch of clearance above the peak of the frosting. Cardboard systems offer superior thermal breathability, allowing heat and moisture to dissipate, but are susceptible to “progressive crushing” in humid environments as cellulose fibers absorb water vapor.

The Thermodynamics of Frosting Preservation

The stability of buttercream is a function of its thermal environment.

- Breathability vs. Steaming: If cupcakes are boxed shortly after baking, the porosity of cardboard is essential to prevent “steaming,” which can cause frosting to melt or liners to peel.

- The Condensation Risk: The significant drawback of airtight plastic clamshells is condensation. If warm cupcakes are sealed, trapped moisture condenses on the lid and drips onto the frosting, causing it to “un-crust” or become sticky. To mitigate this, utilize plastic containers with ventilation holes, or ensure cupcakes reach an internal temperature of 70°F before sealing.

Strategic Implementation for Safe Delivery of the cupcakes in the Boxes.

To guarantee safe delivery, bakeries must adopt a holistic protocol regarding structural fit and load stabilization.

- Precision Sizing: Choosing a container based on visual appeal rather than functional fit is a critical error. A standard cupcake with buttercream requires a box at least 4 inches tall. For elaborate toppers, a 5-inch box is necessary to prevent the lid from “scalping” the frosting during transit vibrations.

- Insert Tolerances: The structural failure of a multi-cavity cardboard system often begins at the insert level. If the circular cutout is not sized precisely to the cupcake liner (typically requiring a 2.5 to 3-inch diameter), the cupcake will tilt, smearing frosting against the adjacent divider.

- Load Stabilization: Containers should be stacked to align their vertical support structures. In cardboard boxes, corners must be perfectly aligned. In plastic individual cupcake containers, the interlocking bases must be engaged to prevent the sliding of units.

Aligning your packaging choices with modern sustainability demands is also crucial. Consider integrating official Forest Stewardship Council (FSC) label requirements if utilizing cellulose-based systems. You can further elevate the visual presentation of these eco-friendly materials by applying professional cake boxes custom printing techniques.

Eliminate transit damage and protect your margins. Standardize your delivery logistics with packaging engineered for kinetic stability. Explore our catalog of premium wholesale custom bakery boxes featuring precision-cut inserts and optimal height clearances for high-swirl frosting.