In the 2026 retail environment, “shelf impact” is measured in milliseconds. Eye-tracking studies confirm that a consumer scans a retail shelf in just 0.05 seconds before their brain decides which product to focus on. If your packaging doesn’t trigger that subconscious “stop” signal, you are invisible.

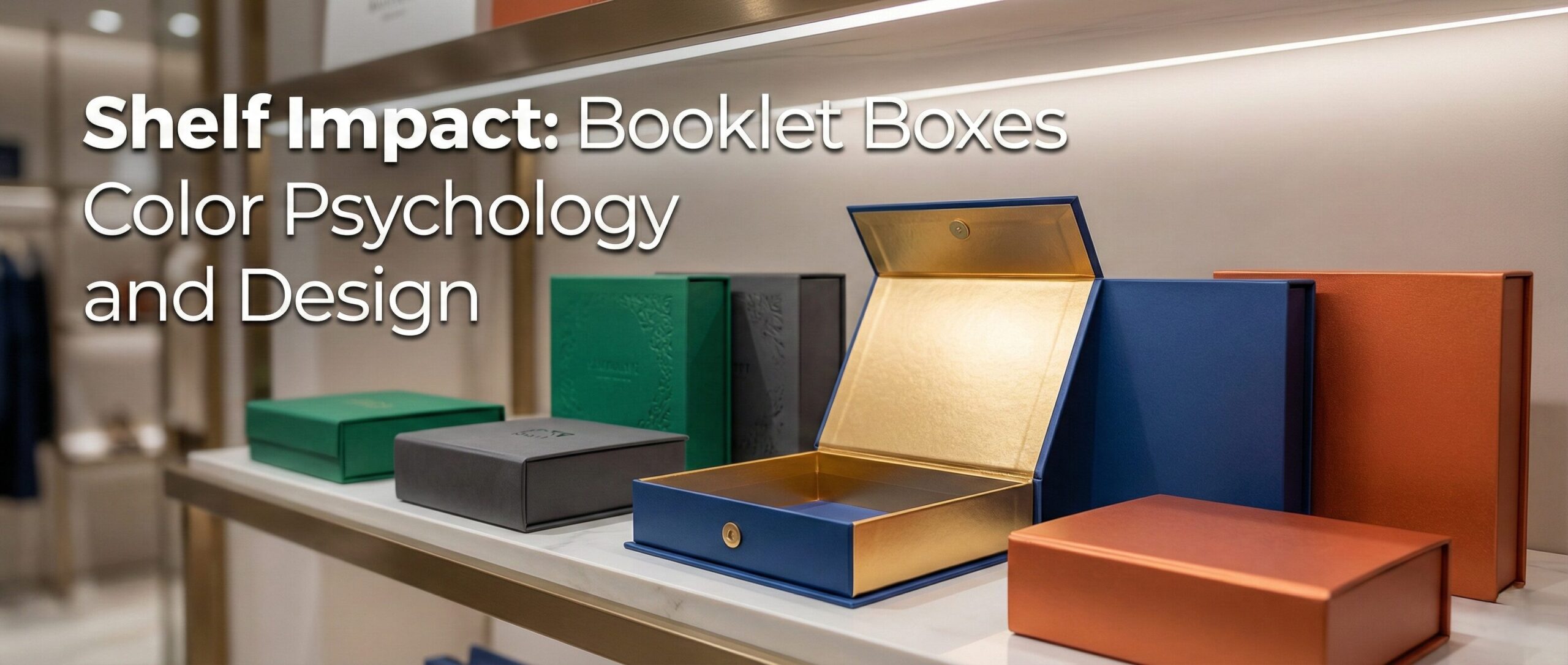

Booklet boxes (often called book-style or magnetic-closure boxes) are the gold standard for “high-perceived value” items like cosmetics, software, and luxury gifts. But a box shape alone isn’t enough. This guide analyzes the color psychology and material engineering required to turn a browser into a buyer.

Neuromarketing: The “First Moment of Truth” (FMOT)

Quick Answer: > Color is the primary driver of the “First Moment of Truth.” In 2026, brands are moving away from generic “minimalist white” toward “Dopamine Brights” and “Digital Pastels” (like Pantone’s 2026 trends) to capture attention. For booklet boxes, a contrasting interior color (e.g., a matte black exterior with a metallic gold interior) increases perceived luxury by 40% compared to single-color designs. Learn in details here.

The “Unboxing” Contrast Effect

The unique advantage of custom booklet boxes is the “reveal.” Unlike a standard tuck-end box, a booklet box opens like a premium novel.

- Exterior: Your “Billboard.” It must scream brand identity.

- Interior: Your “Stage.” This is where the color psychology shifts.

2026 Design Tip: Use the “70/30 Rule.” If your exterior is 70% neutral (for elegance), make the interior 30% vibrant (for excitement). For example, a skincare brand using a “Soft-Touch” white exterior should line the interior tray with a high-gloss “Cyber Lime” or “Fondant Pink” to create a visual dopamine hit upon opening.

Structural Engineering: Rigid Board GSM Standards

Quick Answer: > A booklet box that feels flimsy destroys brand trust instantly. To achieve the “premium book” feel, you must specify 1200 GSM (Grams per Square Meter) Greyboard wrapped in 157 GSM Art Paper. Anything less than 1000 GSM will warp under humidity and feel “cheap” in the consumer’s hand.

The “Thud” Factor

In luxury retail, weight equals value. When a customer picks up your product, the box needs to have density.

- The Core: The structural integrity comes from the Greyboard (chipboard). For booklet boxes wholesale orders, never accept “standard folding carton” stock (18pt or 24pt) if you want a true rigid feel. You need the solid, non-pliable resistance of 2mm thick board.

- The Wrap: The visual layer is usually a thin art paper glued (laminated) over the greyboard. This is where your print quality lives.

Manufacturing Note: Ensure your supplier uses animal-free distinct glues (like localized jelly glue alternatives) if you are marketing to vegan or eco-conscious demographics, a major 2026 purchasing driver.

Haptic Engagement: Soft-Touch vs. Scuff-Free Matte

Quick Answer: > “Haptic Marketing” (marketing through touch) increases ownership desire by 22%. For booklet packaginges, the 2026 industry standard is “Scuff-Free Matte Lamination.” Unlike standard matte, which scratches easily during shipping, scuff-free films use a hardened polymer surface that feels like velvet but resists abrasion, ensuring the box looks pristine on the shelf.

Why Texture Matters for Booklet Boxes

Because booklet boxes are designed to be held and opened repeatedly (often kept as storage boxes by the consumer), the texture is critical.

- Soft-Touch: Feels like peach skin or rubber. High luxury, but can show fingerprints.

- Scuff-Free Matte: The pragmatic choice for wholesale. It protects deep blacks and dark navies from showing white scratch marks during transit.

The Magnetic Closure Mechanics

Quick Answer: > The “snap” of a magnetic closure is a signature sound of quality. For a standard 6×9 inch booklet box, specify two 10mm x 1mm neodymium magnets hidden within the front flap. Weak ferrite magnets often fail to hold the flap shut if the box is slightly overfilled, leading to “shelf pop-open” issues.

Optimizing the “Snap”

Nothing is worse than a booklet box that gapes open.

- Magnet Placement: Magnets must be embedded under the liner paper, not glued on top.

- Polarity Check: A common manufacturing error in custom booklet boxes is reversed polarity, where the magnets repel each other. Always request a “dummy sample” to test the closure force before approving the full run.

Summary: Your 2026 Booklet Box Spec Sheet

To dominate the shelf, your packaging needs to be more than just a container. It needs to be an experience. Use this checklist when talking to your manufacturer:

- Core Material: 1200 GSM Greyboard (2mm thickness).

- Exterior Finish: Scuff-Free Matte Lamination (for durability).

- Closure: Dual 10mm Neodymium Magnets (concealed).

- Interior Design: High-contrast color or foil stamping for the “reveal.”

Ready to create packaging that stops traffic? Don’t let your product blend in. Explore our premium Custom Retail Boxes collection to configure high-impact booklet boxes that combine color psychology with structural engineering.